P: +6017-450 7187

E: cw.lim@la-feeder.com

At LA Feeding, we provide precision custom machining solutions tailored to meet the highest industry standards. With a combination of advanced CNC technology, conventional techniques, and strict quality inspection protocols, we ensure every part meets your exact requirements—whether it’s for prototyping or high-volume production.

Our CNC machining capabilities enable us to deliver high-precision components with tight tolerances and consistent repeatability. Using advanced multi-axis CNC milling and turning centers, we machine complex geometries in a variety of materials, including stainless steel, aluminum, brass, engineering plastics, and specialty alloys.

We work closely with clients to ensure parts are optimized for performance, cost-effectiveness, and integration into your systems or equipment.

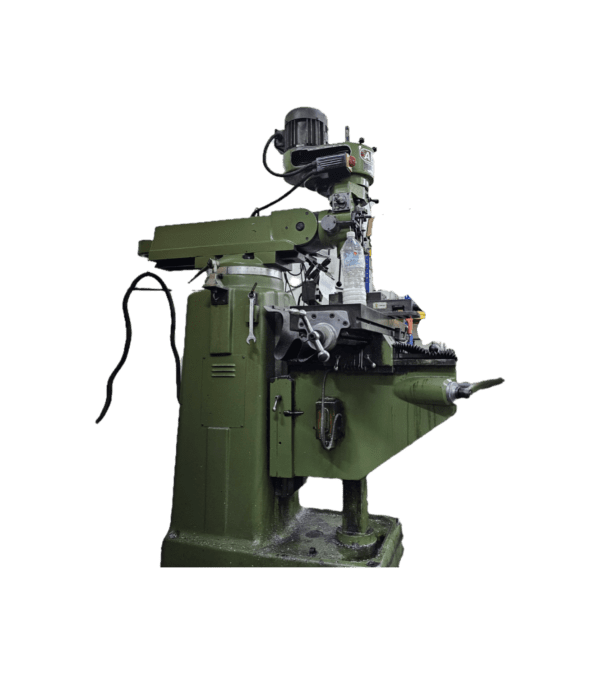

For components that do not require CNC complexity, our conventional machining services offer a cost-efficient solution without compromising on quality. Our skilled machinists operate traditional turning lathes and milling machines to handle a wide range of parts and modifications.

Our conventional machining complements our CNC capabilities, providing flexibility for diverse customer demands.

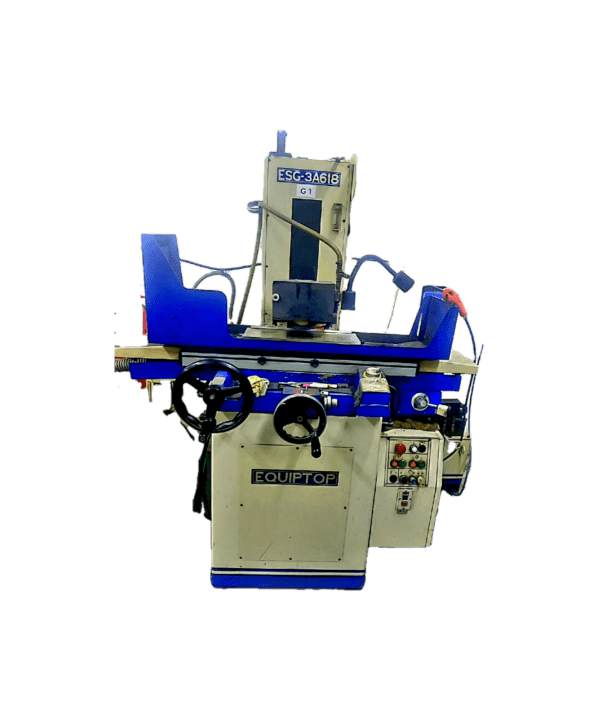

We understand the importance of precision finishing and quality control. Our in-house surface grinding and cylindrical grinding operations ensure ultra-flat and dimensionally accurate finishes, critical for components used in high-performance equipment such as feeding systems, automation lines, and medical tooling.

To maintain the highest standards, we are equipped with measuring instruments such as:

All parts are thoroughly inspected before delivery, ensuring they meet the required specifications and functionality.

LA Feeding’s customized machining services are built on quality, flexibility, and trust. Whether you require a one-off prototype or a fully-machined production batch, we are committed to delivering the precision your project demands.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.