P: +6017-450 7187

E: cw.lim@la-feeder.com

Links:

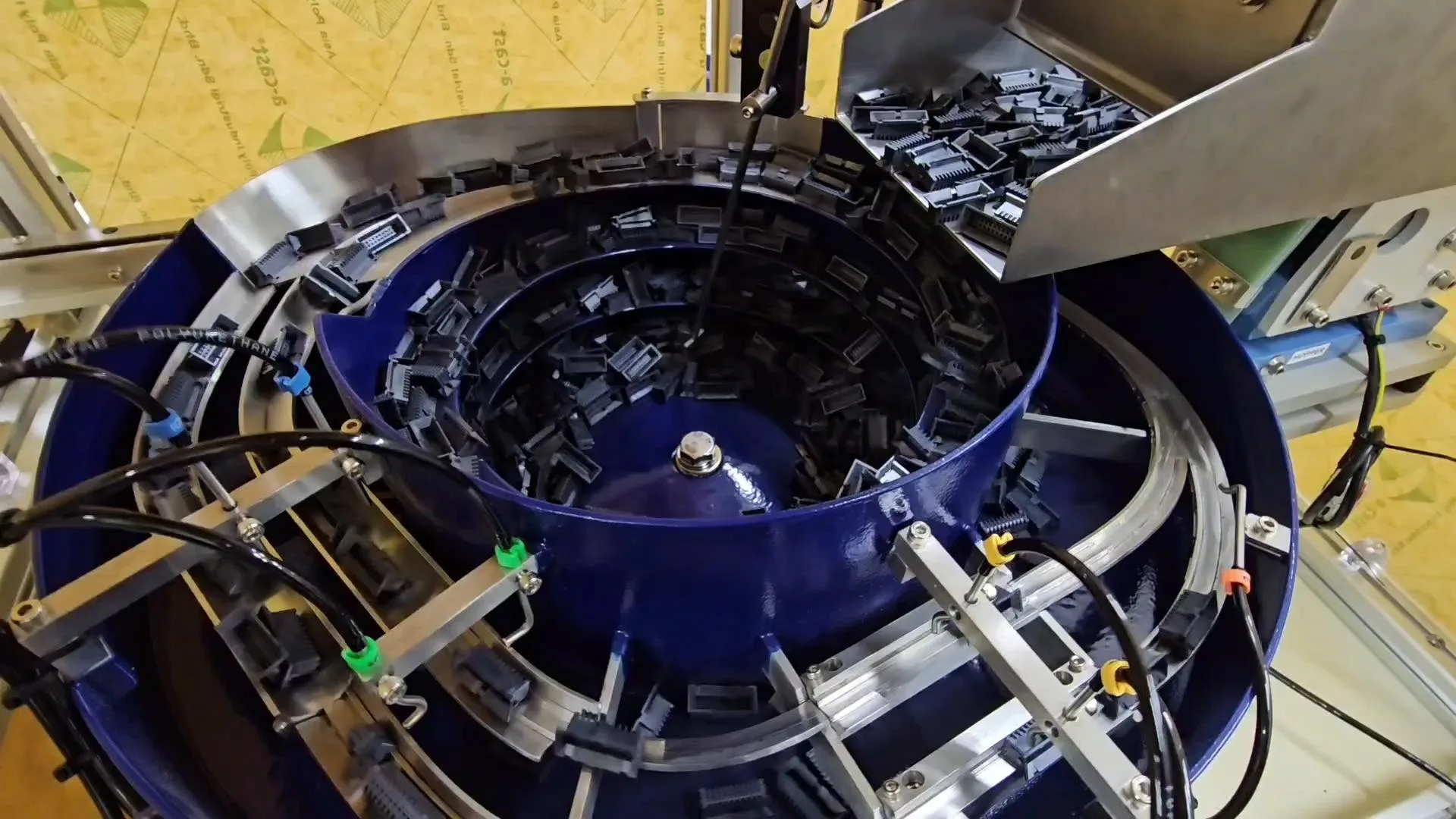

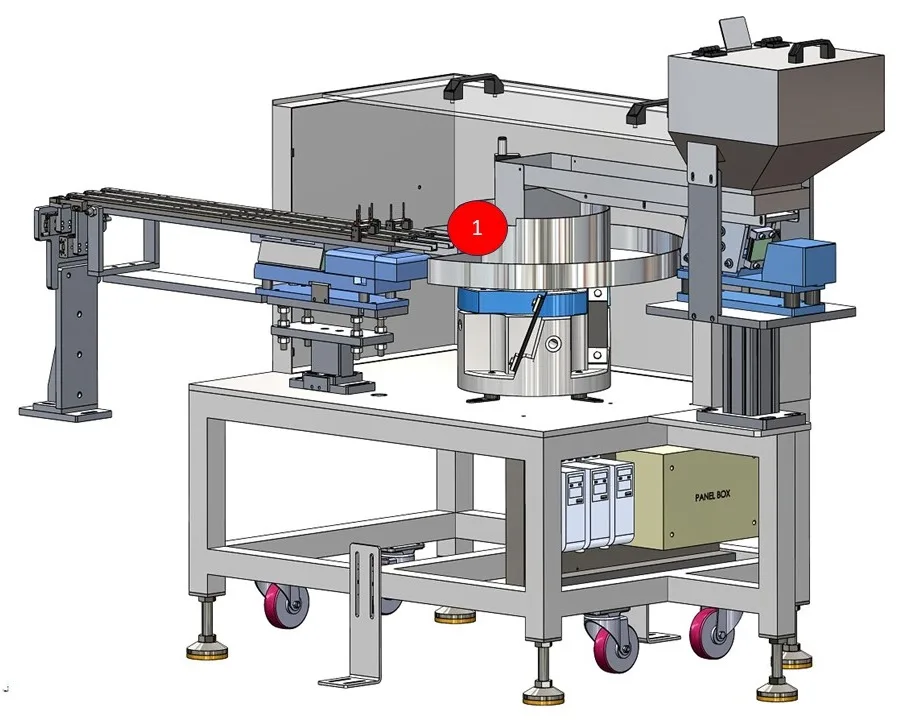

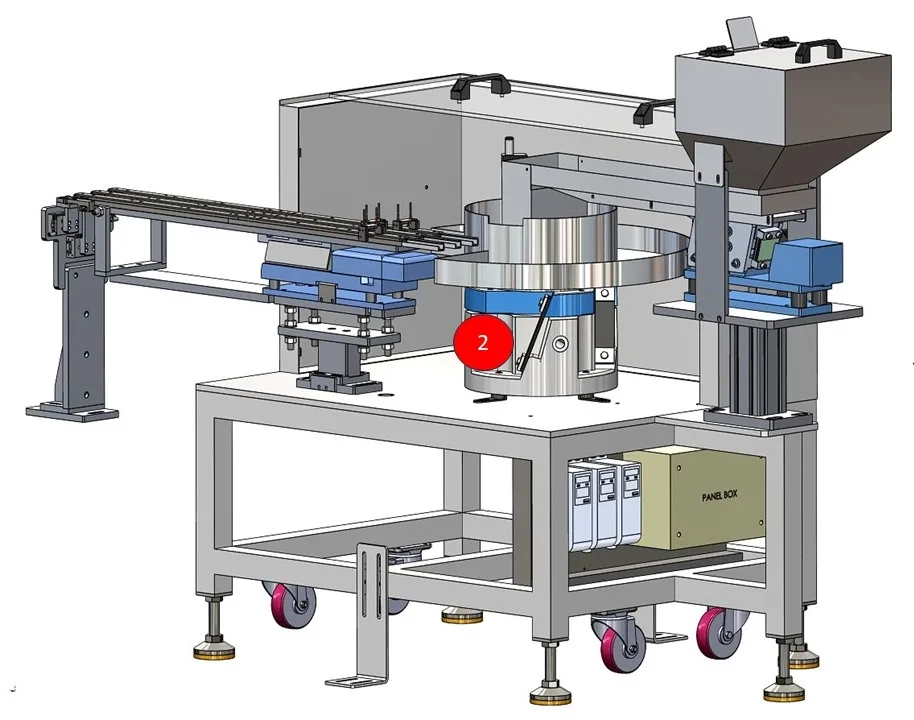

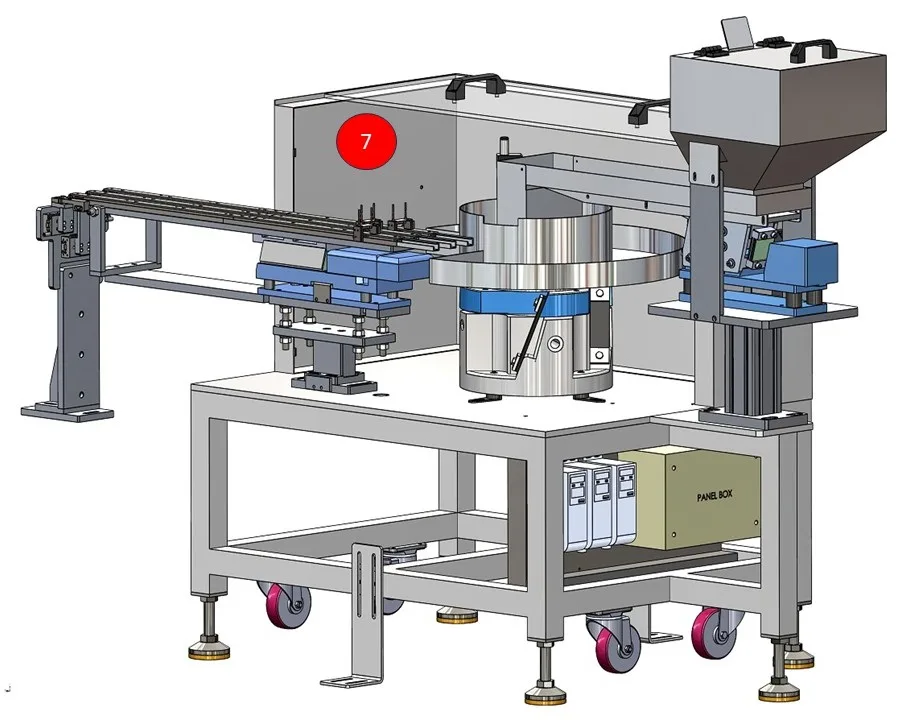

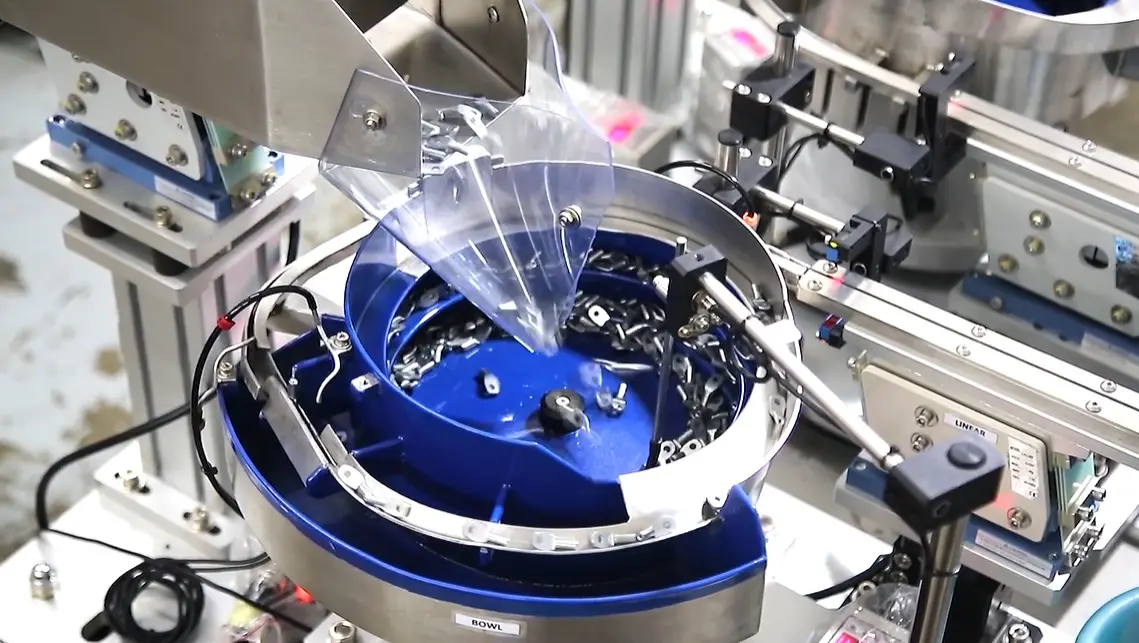

LA Feeding Bowl Top

Links:

LA Feeding Drive Unit

Links:

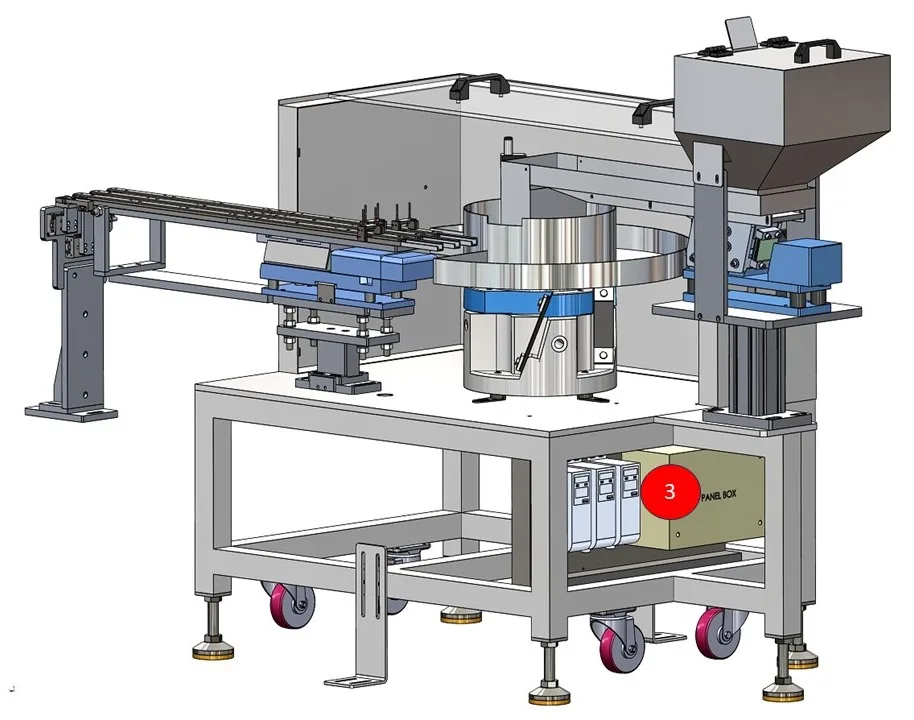

LA Feeding Control Box

Links:

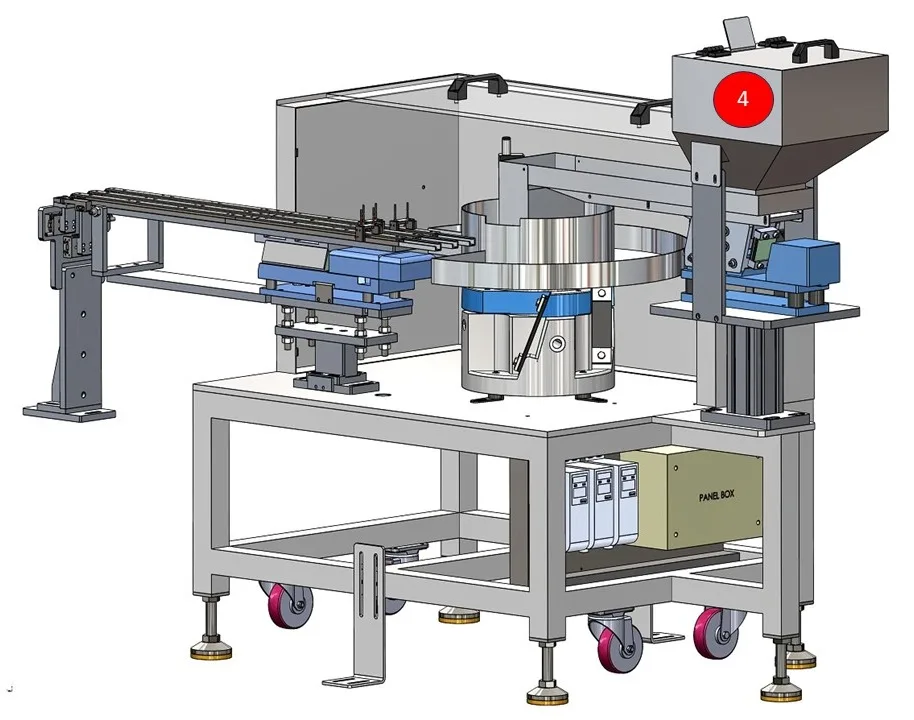

LA Feeding Hopper

Links:

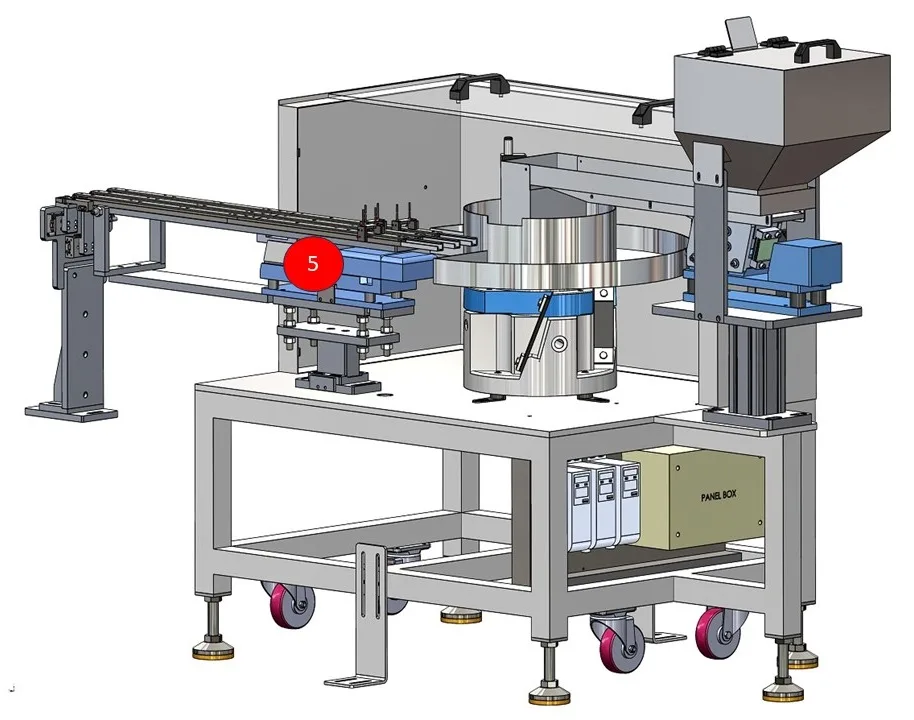

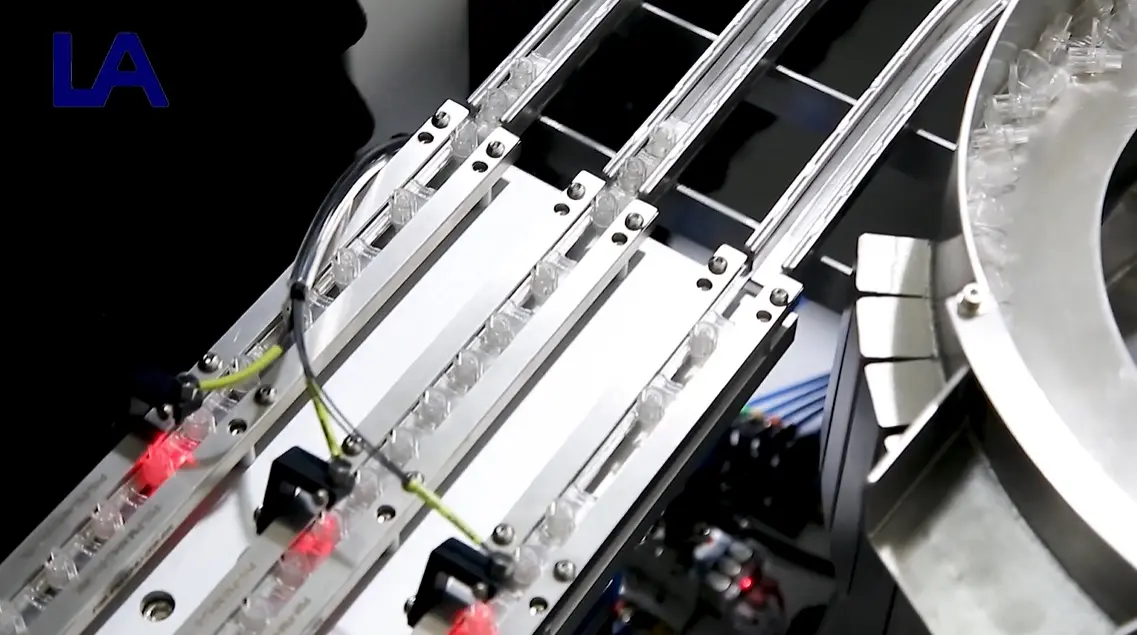

LA Feeding Linear Feeder

Links:

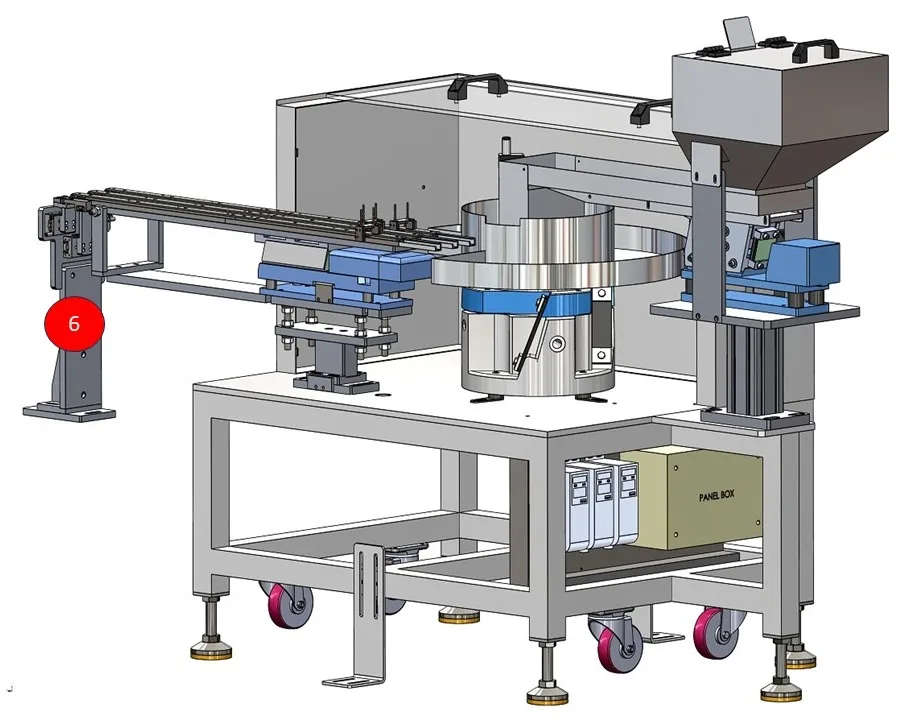

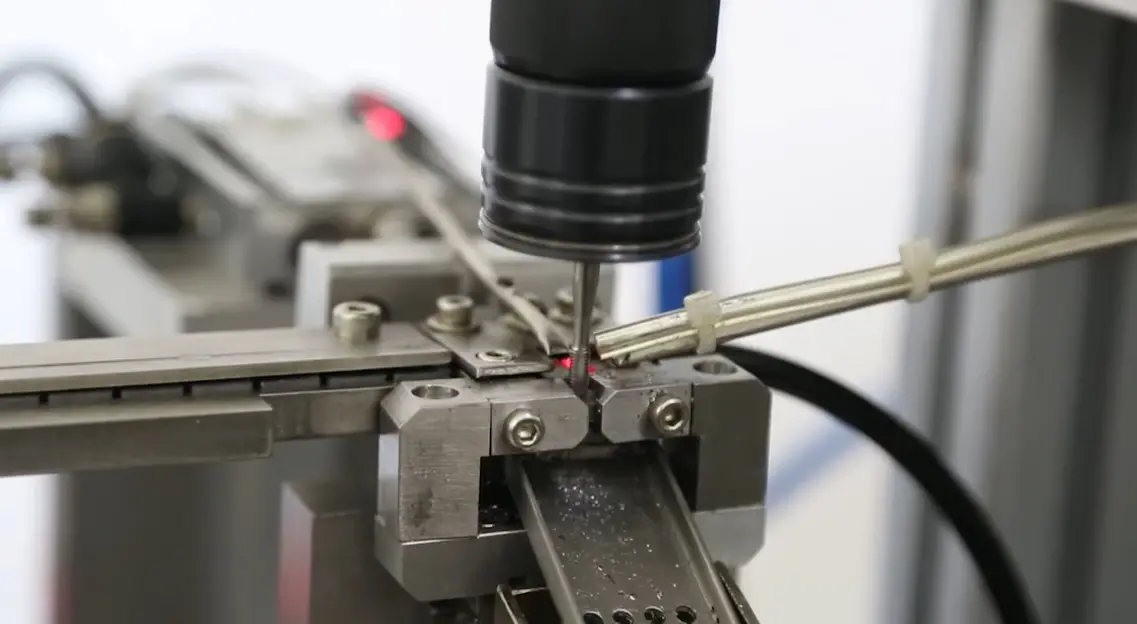

Singulator and Escapements

Links:

Sound Proof Enclosure

ENQUIRY US

We’d love to hear from you. Feel free to contact us and we will be sure to get back to you as soon as possible.